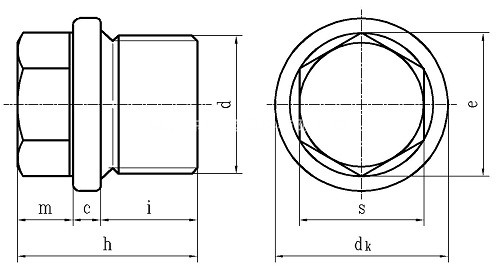

DIN 910 - 2012 帶肩的外六角螺旋塞.重載圓柱螺紋 (標準型)

工藝:

詳細信息

DIN 910 - 2012 帶肩的外六角螺旋塞.重載圓柱螺紋 (標準型)

喉塞是一種裝在管道或螺紋上,主要起到堵塞作用的部件。主要是防止管道內的液體、氣體等泄露。

材質、等級:304不銹鋼、316不銹鋼等,具有不生銹、耐腐蝕、硬度高等優點,可以大大提高使用壽命。

喉塞形狀來分:有內六角喉塞、內六角圓柱頭喉塞、六角頭螺塞等。標準:DIN906、DIN908、DIN910等。

南京東明緊固件有限公司專業銷售喉塞等,如需技術選型及參數請聯系客服。

電話咨詢:400-086-0001 025-86183701-8026

徐小姐

郵件咨詢:dm8026@18luosi.com

QQ咨詢:2850588428

手機咨詢:13584080500

| 公稱直徑 | M10 | M12 | - | - | M14 | M16 | - | - | M18 | M20 | - | - | M22 | M24 | M26 | - | M27 | M30 | M33 | M36 | M38 | M39 | M42 | M45 | M48 | M52 | - | M56 | M60 | M64 | ||

| d | 管螺紋 | G 1/8 A | - | G 1/4A# | G 1/4A | - | - | G 3/8A# | G 3/8A | - | - | G 1/2A# | G 1/2A | - | - | - | G 3/4A# | G 3/4A | - | G 1A | - | G 1 1/8A | - | G 1 1/4A | - | G 1 1/2A | - | G 1 3/4A | - | G 2A | - | |

| P | 螺距 1 | 1 | 1.5 | - | - | 1.5 | 1.5 | - | - | 1.5 | 1.5 | - | - | 1.5 | 1.5 | 1.5 | - | - | 1.5 | - | 1.5 | 1.5 | - | 1.5 | 1.5 | 1.5 | 1.5 | - | - | - | - | |

| 螺距 2 | - | - | - | - | - | - | - | - | - | 2* | - | - | - | - | - | - | 2 | 2 | 2 | 2 | - | 2 | 2 | 2 | 2 | 2 | - | 2 | 2 | 2 | ||

| c | 最小值=公稱 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| 最大值 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | ||

| dk | 最大值=公稱 | 14 | 17 | 18 | 18 | 19 | 21 | 22 | 22 | 23 | 25 | 26 | 26 | 27 | 29 | 31 | 32 | 32 | 36 | 39 | 42 | 44 | 46 | 49 | 52 | 55 | 60 | 62 | 64 | 68 | 72 | |

| 最小值 | 13.57 | 16.57 | 17.57 | 17.57 | 18.48 | 20.48 | 21.48 | 21.48 | 22.48 | 24.48 | 25.48 | 25.48 | 26.48 | 28.48 | 30.38 | 31.38 | 31.38 | 35.38 | 38.38 | 41.38 | 43.38 | 45.38 | 48.38 | 51.26 | 54.26 | 59.26 | 61.26 | 63.26 | 67.26 | 71.26 | ||

| e | 最小值 | DIN 475-1 | - | - | - | - | - | 18.72 | 18.72 | 18.72 | 18.72 | 20.88 | 20.88 | 20.88 | 20.88 | 23.91 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| DIN ISO 272 | 10.89 | 14.2 | 14.2 | 14.2 | 14.2 | 17.59 | 17.59 | 17.59 | 17.59 | 19.85 | 19.85 | 19.85 | 19.85 | 22.78 | 26.17 | 26.17 | 26.17 | 26.17 | 29.56 | 29.56 | 29.56 | 29.56 | 32.95 | 32.95 | 32.95 | 32.95 | 32.95 | 32.95 | 32.95 | 32.95 | ||

| i | 公稱 | 8 | 12 | 8 | 12 | 12 | 12 | 8 | 12 | 12 | 14 | 10 | 14 | 14 | 14 | 16 | 12 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 20 | 20 | 20 | 20 | |

| 最小值 | 7.8 | 11.8 | 7.8 | 11.8 | 11.8 | 11.8 | 7.8 | 11.8 | 11.8 | 13.8 | 9.8 | 13.8 | 13.8 | 13.8 | 15.8 | 11.8 | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 19.8 | 19.8 | 19.8 | 19.8 | ||

| 最大值 | 8.2 | 12.2 | 8.2 | 12.2 | 12.2 | 12.2 | 8.2 | 12.2 | 12.2 | 14.2 | 10.2 | 14.2 | 14.2 | 14.2 | 16.2 | 12.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | 20.2 | 20.2 | 20.2 | 20.2 | ||

| h | ≈ | 17 | 21 | 17 | 21 | 21 | 21 | 17 | 21 | 24 | 26 | 22 | 26 | 26 | 27 | 30 | 26 | 30 | 30 | 32 | 32 | 32 | 32 | 33 | 33 | 33 | 33 | 40 | 40 | 40 | 40 | |

| m | 公稱 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 9 | 10 | 10 | 10 | 10 | 11 | 11 | 11 | 11 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | |

| 最小值 | 5.76 | 5.76 | 5.76 | 5.76 | 5.76 | 5.76 | 5.76 | 5.76 | 7.71 | 7.71 | 7.71 | 7.71 | 7.71 | 8.71 | 9.71 | 9.71 | 9.71 | 9.71 | 10.65 | 10.65 | 10.65 | 10.65 | 11.65 | 11.65 | 11.65 | 11.65 | 14.65 | 14.65 | 14.65 | 14.65 | ||

| 最大值 | 6.24 | 6.24 | 6.24 | 6.24 | 6.24 | 6.24 | 6.24 | 6.24 | 8.29 | 8.29 | 8.29 | 8.29 | 8.29 | 9.29 | 10.29 | 10.29 | 10.29 | 10.29 | 11.35 | 11.35 | 11.35 | 11.35 | 12.35 | 12.35 | 12.35 | 12.35 | 15.35 | 15.35 | 15.35 | 15.35 | ||

| s | DIN 475-1 | 最大值 | - | - | - | - | - | 17 | 17 | 17 | 17 | 19 | 19 | 19 | 19 | 22 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 最小值 | - | - | - | - | - | 16.57 | 16.57 | 16.57 | 16.57 | 18.48 | 18.48 | 18.48 | 18.48 | 21.16 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | ||

| DIN ISO 272 | 最大值 | 10 | 13 | 13 | 13 | 13 | 16^ | 16^ | 16^ | 16^ | 18^ | 18^ | 18^ | 18^ | 21^ | 24 | 24 | 24 | 24 | 27 | 27 | 27 | 27 | 30 | 30 | 30 | 30 | 36 | 36 | 36 | 36 | |

| 最小值 | 9.64 | 12.57 | 12.57 | 12.57 | 12.57 | 15.57 | 15.57 | 15.57 | 15.57 | 17.57 | 17.57 | 17.57 | 17.57 | 20.16 | 23.16 | 23.16 | 23.16 | 23.16 | 26.16 | 26.16 | 26.16 | 26.16 | 29.16 | 29.16 | 29.16 | 29.16 | 35 | 35 | 35 | 35 | ||

| 千件重kg | 12 | 20.3 | 20 | 23.8 | 25 | 35.2 | 32.2 | 38.1 | 48.6 | 64.5 | 57.8 | 66.6 | 73.4 | 93.5 | 120 | 109 | 127 | 148 | 195 | 220 | 238 | 255 | 300 | 340 | 375 | 430 | 572 | 620 | 695 | 774 | ||

| ①,* 僅用于關閉分度閥的螺紋孔。 | ||||||||||||||||||||||||||||||||

| ②,# 盡可能避免使用短螺絲的這些尺寸。 如果在特殊情況下需要它們,則螺紋長度i必須在名稱中注明,例如: | ||||||||||||||||||||||||||||||||

| 螺塞DIN 910 - G 1/4 A×8 - St | ||||||||||||||||||||||||||||||||

| ③,^ 對于對邊寬度SW 16,SW 18和SW 21,為了避免混淆,必須在名稱中標明對邊寬度。 | ||||||||||||||||||||||||||||||||

| ④,不同對邊寬度的重量略有不同。 | ||||||||||||||||||||||||||||||||

| ⑤,管螺紋對應標準為DIN EN ISO 228-1 | ||||||||||||||||||||||||||||||||

| ⑥,公制細螺紋標準為 DIN 13-5, -6 或 -7 | ||||||||||||||||||||||||||||||||